Case studies | Find examples on decarbonization measures, costs and regulations to benchmark your business case

Business case for an offshore construction vessel with a shore power battery

This case study evaluates a mobile shore power battery barge designed for an offshore construction vessel in the Port of Rotterdam. An average power demand of 2.4 MW and a peak demand of 5 MW is assumed. This results in the requirement of twelve 20-ft containerized batteries integrated into a High Voltage Shore Connection (HVSC) system. Total costs of the power barge are estimated at $9.5M with a yearly revenue of approx. $2.5M.

Fuel and compliance costs for offshore workboat in North Sea

Operating an offshore workboat in the North Sea area until 2050 will impose significant financial and operational pressure due to tightening environmental regulations and mounting compliance obligations. Modelling of compliance costs shows a clear tipping point in 2040, with FuelEU Maritime becoming the dominant driver, although FuelEU currently applies to vessels above 5,000 GT only. Results for a large offshore workboat operating year-round in the North Sea show that the maximum projected cost exposure could reach up to $250 million between now and 2050.

Ship-Based Carbon Capture Techno-Economic Guide

This blog provides techno-economic guidance for the use of SBCC onboard your vessel, including operational impact, logistics and of course the costs for implementation. Key points include the following; SBCC is applicable to virtually all ship types, sizes and fuel type but LNG is preferred. SBCC produces 2 m3 of CO2 per day per MW. SBCC costs €115 per ton CO2, is a CAPEX dominated technology and costs €175k per MW.

MoU for North Star Support Vessels on Offshore Wind

Maersk’s Stillstrom and North Star have signed a Memorandum of Understanding (MoU) to accelerate the adoption of offshore charging and vessel electrification technologies for Offshore Support Vessels (OSVs) in the offshore wind sector. Offshore charging hubs will enable the vessels to recharge their battery systems using wind energy while in the field.

Hydrogen Powered Propulsion for an Offshore Crane Vessel

This thesis performs a technical, economical and environmental feasibility study of three dense hydrogen carriers as a fuel to power the largest semi-submersible offshore crane vessel in the world – Heerema’s Sleipnir.

Get Ready for the Alfa Lift, an Electric-Hybrid Heavy Lift Crane Vessel

The Alfa Lift, a new build heavy lift crane vessel owned by Offshore Heavy Transport, is on track to enter service by early 2022. The vessel features a 3,000 ton main crane, 10,000+ m² smart deck which can be fully submerged to a depth of 15 meters and a electric-hybrid battery system made by Kongsberg.

The Big Friendly Hybrid Giant

The North Sea Giant, a Norwegian offshore construction vessel, is the first DNV class-approved ‘hybrid’ DP3 vessel with three batteries on-board that have a total capacity of 2.034 kWh. The batteries have been installed in an upgrade and serve the purpose of spinning reserve, peak shaving and load leveling. Since then, fuel consumption is reduced in all operational modes with over 2 million liters of diesel per year, saving up to 30% fuel.

Making the Impossible Possible

This blog sketches a vision on how to convert the largest crane vessel in the world - Sleipnir - owned by Heerema Marine Contractors, to a zero-emission vessel. Several promising carbon reduction measures are combined which are technically viable and based on matured technology including electrification and BES, solar panels, synthetic fuels, CCS and possibly hydrogen combustion.

Ørsted and Maersk to Test Offshore Vessel Charger

Maersk and Ørsted are building a ‘power-buoy’ that can act as both a mooring point and a charging station for vessels, enabling them to turn of their engines when laying idle.

Amazing Power of North Sea Giant

North Sea Giant is amongst the largest and most advanced subsea construction vessels ever built. North Sea Giant is an efficient multi-purpose vessel with supreme deck and crane capacity, alongside a unique power system. Her propellers and thrusters are tailor made for delivering a wide variety of demanding marine operations in deep and ultradeep waters.

How the North Sea Giant saves two million liters of diesel every year

The North Sea Giant saves two million liters of diesel every year. It has installed three battery packs and a distribution system from Wärtsilä, which will dramatically reduce fuel consumption. The North Sea Giant is one of the world's largest construction ships, and was the first vessel in its class to have a hybrid system installed on board.

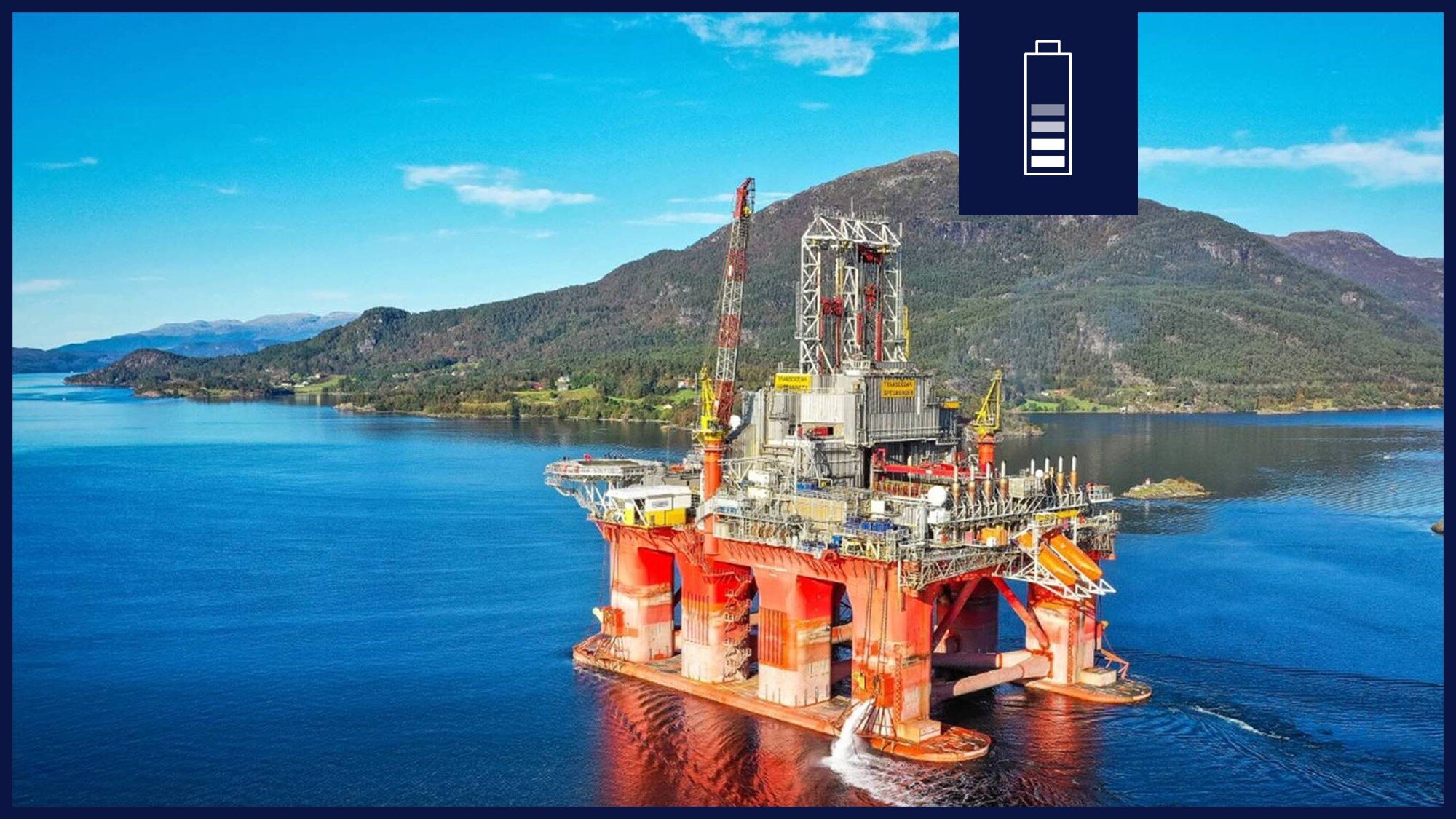

Transocean Spitsbergen goes Hybrid

In April 2019, the Transocean Spitsbergen successfully and sagely installed an electric Energy Storage System (ESS) of 5.6 [MW] on-board. This allowed the semi-submersible drillship to run in hybrid mode during DP3, reducing fuel consumption by about 15%. Economic incentives were provided in the fuel-clause and by the Norwegian NOx Fund.