Hydrogen

This page is all about hydrogen, how to produce and store it, and how to use it on-board your vessel. Do you have questions or would you like to contribute ideas? Scroll down to comment or contact experts directly here.

Key Lessons

How much does hydrogen fuel cost? How much do elektrolysers cost? Everything you need to build a business case!

Our finest selection of blogs, movies and podcasts

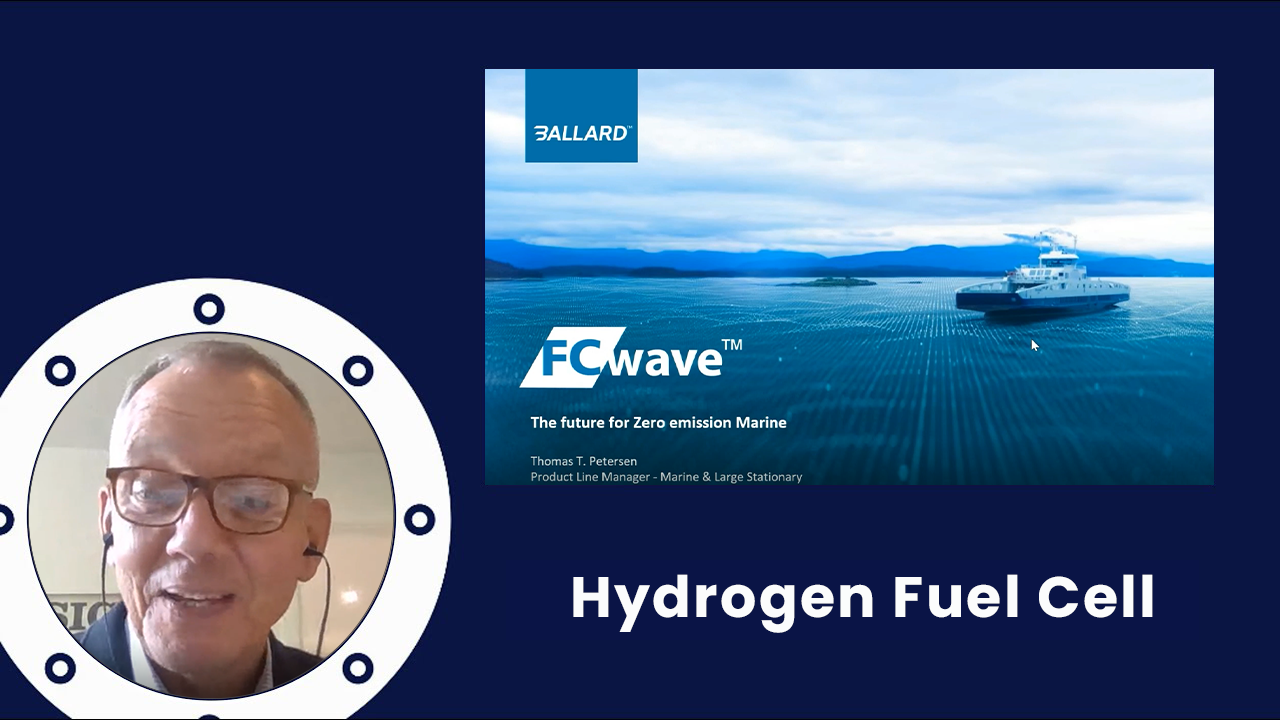

Join Thomas Therkild Petersen as he presents the FCWave, a modular 200 kW hydrogen fuel cell for marine purposes made by Ballard. It is the only DNV type approved hydrogen fuel cell on the market. At the size of a large cabinet, it can be directly integrated into most engine rooms without a hitch. Watch this video to gain insights on one of the best hydrogen fuel cell systems available for the maritime industry.

As the world’s first type approved module for marine applications, FCwaveTM uses proven technology from Ballard's heavy duty module platform to deliver reliable performance, high power density and favorable economics.

This thesis performs a technical, economical and environmental feasibility study of three dense hydrogen carriers as a fuel to power the largest semi-submersible offshore crane vessel in the world – Heerema’s Sleipnir.

Over 20% of all Dutch emissions are coming from the Port of Rotterdam, of which the production of grey hydrogen from fossil feedstock is one of the main culprits. This article explores what is needed to build a green hydrogen refinery. It provides an overview of the existing fossil infrastructure and fuel consumption, which technologies are required to transform, how much it would cost and who are actually working on it.

A curious coincidence In Rotterdam. Two vessels - the ‘MS Antonie’ and ‘the Maas’ claim to become ‘the first hydrogen inland vessel’ in Rotterdam. We have translated their claims from two Dutch news outlets and made a comparison which might help you on your hydrogen journey. The race is on for the first hydrogen-powered inland vessel in Rotterdam!

This thesis by J.M. Rozendaal at van Oord focuses on the technical, environmental and economic impact of a methanol hybrid power plant design for new-build offshore working vessels. Its conclusion is that a methanol solution has a CO2 reduction potential up to 99% and a CO2 price of 78 euro per ton CO2 reduction.

BP and Ørsted have partnered to develop a zero-carbon hydrogen at BP’s Lingen Refinery in north-west Germany, BP's first full-scale project in a sector that is expected to grow rapidly. The 50 MW electrolyser project is expected to produce 1 ton of hydrogen per hour - almost 9,000 tonnes a year - starting in 2024. The project could be expanded to up to 500 MW at a later stage to replace all of Lingen’s fossil fuel-based hydrogen.

Hydrogen is a clean-burning molecule, meaning that it can help to decarbonize a range of sectors that have proved hard to clean up in the past. But today, most hydrogen is produced from CO2-emitting fossil fuels. Hydrogen produced from renewable electricity, known as green hydrogen, could be the solution to cutting our carbon footprint. But first, it must overcome a number of challenges.

Heliogen, backed by Bill Gates, makes fuel out of thin air and sunlight. It simply costs a lot of energy.

This blog sketches a vision on how to convert the largest crane vessel in the world - Sleipnir - owned by Heerema Marine Contractors, to a zero-emission vessel. Several promising carbon reduction measures are combined which are technically viable and based on matured technology including electrification and BES, solar panels, synthetic fuels, CCS and possibly hydrogen combustion.

Ask us anything

Getting you in the right mindset before you dive into the subject